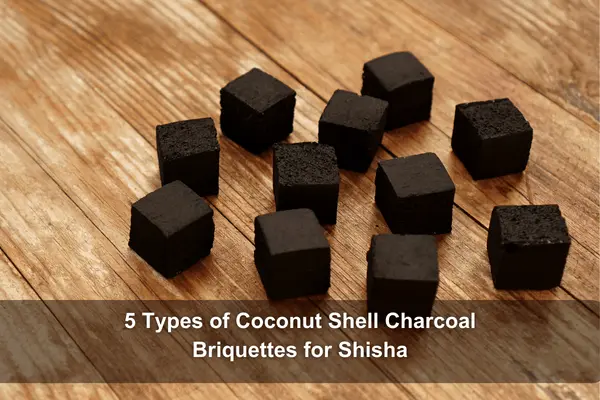

5 Types of Coconut Shell Charcoal Briquettes for Shisha

The first thing that is very important when you want to use a shisha is charcoal briquettes. We recommend you use charcoal from coconut shells for shisha. This time we will discuss types of coconut shell charcoal briquettes for shisha. There are 5 types of charcoal coconut shells based on their size and shape. To …

5 Types of Coconut Shell Charcoal Briquettes for Shisha Read More »